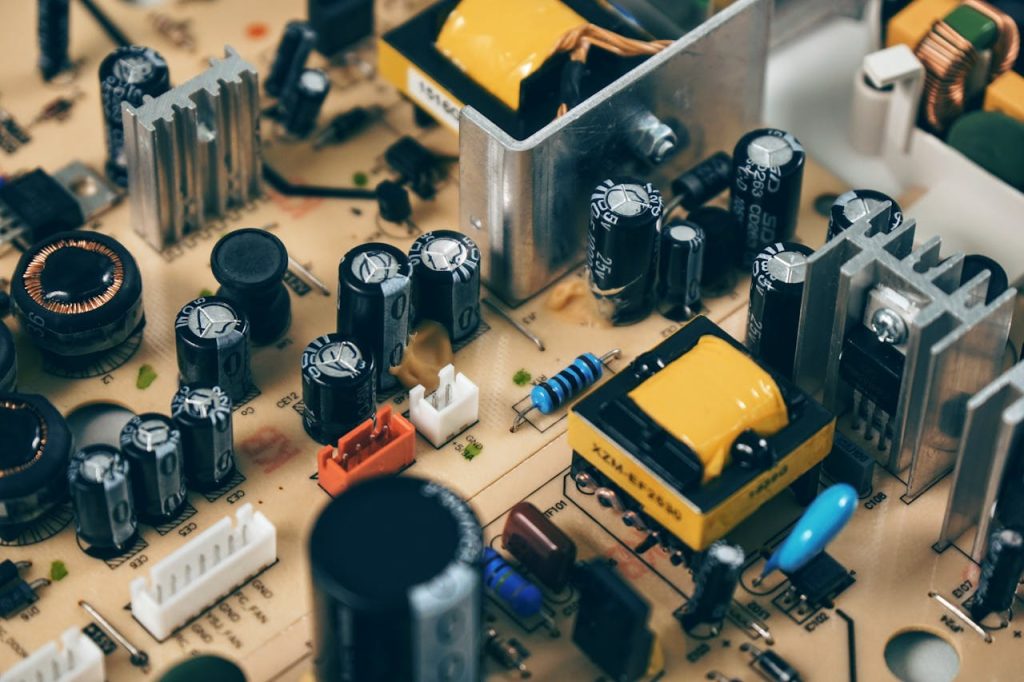

Electronics manufacturing facilities often face challenges in maintaining optimal working conditions during warmer months. With machinery generating heat and external temperatures rising, internal temperatures can soar above 30°C, even when outdoor conditions are significantly cooler. This not only creates an uncomfortable environment for employees but can also affect the quality of delicate manufacturing processes.

Evaporative cooling systems, such as Breezair units, offer an efficient and effective solution for electronics facilities. By installing multiple units, manufacturers can achieve consistent and comfortable internal temperatures, often reducing them to around 20°C, even during peak summer heat.

Beyond cooling, evaporative systems provide an added benefit: maintaining an optimal level of relative humidity. For electronics manufacturing, this is critical as higher humidity minimises electrostatic discharge during assembly, reducing the risk of component failure and enhancing overall production reliability.

Evaporative cooling is more than just a temperature control solution—it’s a cost-effective way to improve working conditions, protect sensitive equipment, and optimise manufacturing outcomes Learn how evaporative cooling helped improve your facility – read our case study